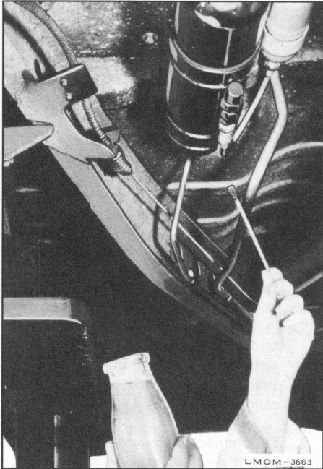

Fig. 17. Check for Leaks - (Step 3)

figure 17. NOTE: It is suggested that

some Freon be allowed to escape from a

Freon tank at some distance from the

vehicle. This Freon can then be detected

with the Leak Detector, Tool - ACL53-

2, and the exact color of the flame

4. If Freon is detected, it may be pin-

pointed exactly by using Liquid Leak

Detector. The liquid solution, when mixed

according to instructions and "painted on" a

leak, will form bubbles around the exact

location. See figure 18.

5. Repair all leaks and turn off the flame in

Leak Detector, Tool - ACL53-2.

REMOVAL OF COMPRESSOR

ASSEMBLY

1. Drain coolant from radiator and cylinder

block.

2. Install Pressure Test Gauge Manifold,

Tool - ACL53-3, with both gauge

valves turned in the full clockwise

position so that the high

Fig. 18. Check for Leaks - (Step 4)

pressure gauge hose is connected to the

high pressure valve service port and the

low pressure gauge hose is connected to

the low pressure valve service port.

3. Turn low pressure valve, located on right

front fender apron, and high pressure valve,

located on the condenser, 1-1/2 turns in the

clock-wise direction, using Tool-ACL53-5.

Both gauges will read neutral sys-tem

pressure (Approximately 50 - 7 5 P.S.I. at

an outside air temperature of approximately

70

0

- 750). See figure 11.

4. If both gauges read neutral system

pressure, pump system down by following

"Pump Down Procedure".