the inverted air horn on a level

surface so the

float can be gauged (consult Holley

catalog sheets

for the proper float gage, part number

and speci

fications.) Reset the gage on the

float horizontal

surface of the air horn with the

gage just touching

the float, but not lying across

the soldered seam.

Make adjustments by bending the

rounded tab,

which contacts the head of the fuel

inlet needle

(see "A" in Figure 38).

When the properly closed

float reading has been made, lift

the float to the

full open position. Any accurate

depth gage may

then be used to measure the distance

from the

float to the air horn. Adjustments

on the float

lever to limit the travel may be

made only by

bending the small tab which contacts

the side of

the fuel inlet seat (see "B"

in Figure 38).

E.

REASSEMBLY - AIR HORN ASSEMBLY

MODEL 2110-G

1. Slide choke shaft in position

in the

air horn. Insert the choke plate

in slot of the choke

shaft. (Correct shaft position noted

during dis

assembly.) Install choke plate screws

snugly but

not tight. Rotate the choke shaft.

If no binding

occurs and little or no light appears

between the

plates and the walls of the bore

when plates are

closed, tighten the choke plate

screws securely.

Using a suitable staking tool, stake

the choke plate

screws.

2. Slide the choke wire bracket

as

sembly on the choke shaft, place

the throttle spring

lever in position and install the

screw and lock

washer. Place the choke lever clamp

on the choke

shaft in the correct position and

install the screw

and nut.

3. Install fuel inlet valve and

seat as

sembly, using Kent-Moore Tool No.

10-183.

Tighten securely to prevent leakage

past the new

gasket. Check to make certain the

fuel inlet needle

is inserted with the point up towards

seating sur

face.

only by bending the rounded tab

which contacts

the fuel needle. (See "A"

in Figure 38). Afterthe

proper closed setting has been

made, lift thefloat

to"°the full open position.

Any accurate depth gage

may be used

to measure the distance from the

float to the air horn. Adjustments

on the float

lever may be made to limit the

travel of the float

only by bending the small tab which

contacts the

side of the fuel inlet valve seat.

(See "B" in Fig

ure 38.)

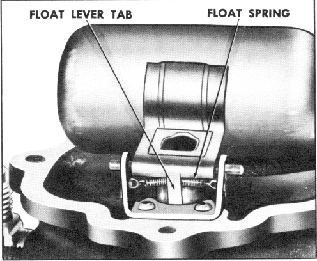

Fiqure 39. Correct Position of

Float Spring

5. Install the fuel inlet connection

and

the governor line connection fitting.

F.

REASSEMBLY - THREE MAJOR

SUBASSEMBLIES MODELS 2110-EE,

2110-EEC AND 2110-FF

1. Place a new throttle body gasket

on

the throttle body and align the

holes. Set the main

body on the throttle body, taking

care that the holes

in the gasket remain in alignment.

Position the

choke bracket or control rod bracket

- if included.

Insert the three throttle body

to main body screws

and lockwashers.

NOT

4. Install float spring and float

spring

retainer. Holding the float and

lever assembly

in position, slide the float shaft

into position.

Place the inverted air horn on

a level surface so

the float can be gaged. (Consult

current Holley

Catalog sheets for proper float

gage, part number,

and specifications.) Reset the

gage on the flat

horizontal surface of the air horn

with the gage

just touching the float. Do not

gage the float on

the soldered seam. Adjustments

should be made

Tighten the three screws alternately,

a little

at a time, to compress the gasket

evenly.

2. Install the pump link. The three

holes in the throttle lever permit

adjustment of

the accelerating pump discharge.

The outer hole

provides a maximum pump discharge

for extreme

cold weather operation, and the

inner hole pro

vides a minimum pump discharge

for hot weather.

However, for most driving conditions,

the middle

hole should be used.

Install the two retainers.

-27-