Other Quadrajet carburetors use a dual delayed vacuum break system consisting of a front or main vacuum break diaphragm unit and a rear or auxiliary vacuum break diaphragm unit (Figure 22).

The dual delayed vacuum break system operates as follows:

During engine cranking, the choke valve is held closed by the tension of the thermostatic coil. This restricts air flow through the carburetor to provide a richer starting mixture.

When the engine starts and is running, manifold vacuum is applied to both vacuum break diaphragm units mounted on the side of the float bowl. The front or main vacuum break diaphragm opens the choke valve to a point where the engine will run without loading or stalling. As the engine is wetted and friction decreases after start, an internal bleed in the auxiliary vacuum break unit causes a delayed action to gradually open the choke valve a little further until the engine will run at a slightly leaner mixture to prevent loading.

Included in the auxiliary vacuum break unit is a spring-loaded plunger. The purpose of the spring is to offset choke thermostatic coil tension and balance the opening of the choke valve with tension of the choke coil. This enables further refinement because the coil, which senses engine temperature, will allow the choke valve to open gradually against spring tension in the diaphragm plunger head.

A clean air purge feature is added to the rear or auxiliary vacuum break diaphragm unit on some 4MV models using the dual delayed vacuum break system (Figure 22). A clean air bleed, added to the tube at the rear of the auxiliary vacuum break unit and located beneath a rubber covered filter, purges the system of any fuel vapors and dirt which may possibly enter the internal check bleed valve to disrupt operation. A change in adjustment procedure for setting the auxiliary vacuum break is required on those models using the clean air purge feature. (See Adjustment Procedures, Section 5, of the Delco Carburetor Parts and Service Manual 9X).

CHOKE SYSTEM (4MC EARLY)

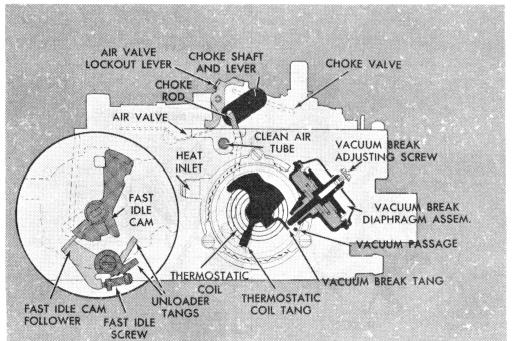

The early Model 4MC choke system (Figure 23) consists of a choke valve located in the primary air horn bore, a choke housing and vacuum diaphragm assembly, fast idle cam, connecting linkage, air valve lockout lever, and thermostatic coil. Choke operation is controlled by the combination of intake manifold vacuum, the offset choke valve, temperature, and throttle position.

The thermostatic coil is calibrated to hold the choke valve closed when the engine is cold.

NOTE: To close the choke valve, the primary throttle valves have to be partially opened to allow the fast idle cam follower to by-pass the steps on the fast idle cam and come to rest on the highest step of the fast idle cam.

CHOKE SYSTEM - 4MC (EARLY) (Fig. 23)

FIGURE 23

When the choke valve is closed, the air valve lockout lever is weighted so that a tang on the lever catches the upper edge of the air valve and keeps the air valve closed.

During engine cranking, the choke valve is held closed by the tension of the thermostatic coil. This restricts air flow through the carburetor to provide a richer starting mixture. When the engine starts and is running, manifold vacuum applied to the vacuum diaphragm unit mounted on the float bowl, opens the choke valve to a point where the engine will run without loading or stalling. This is accomplished through an adjustable plastic plunger mounted on the vacuum break diaphragm. Engine vacuum pulls inward on the diaphragm and the plunger strikes the vacuum break tang inside the choke housing which, in turn, rotates the intermediate choke shaft and through connecting linkage opens the choke valve. At the same time, the fast idle cam follower lever on the end of the primary throttle shaft will drop from the highest step on the fast idle cam to the second step if the throttle is opened. This gives the engine sufficient fast idle and correct fuel mixture for running until the engine begins to warm up and heat the thermostatic coil. As the thermostatic coil becomes heated, it relaxes its tension and allows the choke valve to open further because of intake air pushing on the offset choke valve. Choke valve opening continues until the thermostatic coil is completely relaxed and the choke valve is wide open.

During engine warmup the choke coil rotates, forcing the intermediate choke shaft and lever clockwise. This allows the fast idle cam to rotate until the cam follower drops off the last step of the fast idle cam so the engine will run at normal idle speeds. When the choke moves toward the open position, the end of the choke rod strikes a tang on the air valve lockout. As the choke rod moves to the end of its travel, it pushes the lockout tang upward and unlocks the air valve.