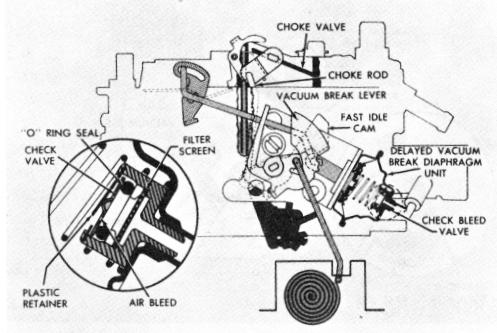

CHOKE SYSTEM (Fig. 20)

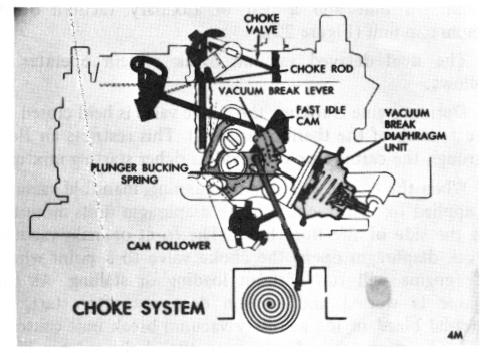

CHOKE SYSTEM (Fig. 21)

FIGURE 20

Some models use a delayed vacuum break system. This system operates as follows:

When the engine is started cold, vacuum is applied to the choke vacuum break diaphragm unit, opening the choke valve against tension of the thermostatic choke coil to a point where the engine will run without loading or stalling.

To delay the choke valve from opening too fast, an internal air bleed check valve is used inside the diaphragm unit. When the engine starts, vacuum acting on the internal check valve bleeds air through a small hole in the valve which allows the vacuum diaphragm plunger to move slowly inward. This gives sufficient time to overcome engine friction and wet the engine manifold to prevent a lean stall. When the vacuum break diaphragm is fully seated, which takes a few seconds, the choke valve will remain in the vacuum break position until the engine begins to warm and relax the thermostatic coil located on the exhaust crossover in the intake manifold.

In addition to the internal bleed check valve, some car applications have a separate vacuum delay tank added to the system. This is connected "in series" to a second vacuum tube on the vacuum diaphragm unit to further delay the choke vacuum break diaphragm operation.

The check valve in the choke vacuum diaphragm unit is designed to "pop" off its seat and allow the diaphragm plunger to extend outward, when the spring force against the diaphragm is greater than the vacuum pull. This will give added enrichment as needed on heavy acceleration during cold drive-a-way by allowing the choke coil to slightly close the choke valve. Some 4MV models use a calibrated restriction in the vacuum inlet to the vacuum break diaphragm unit in place of the internal air bleed check valve. Similar to the internal air bleed check valve, the calibrated restriction delays the supply of vacuum to the diaphragm unit to retard opening of the choke valve for good engine starting.

FIGURE 21

A spring loaded plunger is used in the vacuum break unit on some 4MV models (Figure 21). The purpose of the spring, called a "bucking spring," is to offset choke thermostatic coil tension and balance the opening of the choke valve with tension of the choke coil. This enables further refinement of air/fuel mixtures because the coil, which senses engine and ambient temperatures, will allow the choke valve to open gradually against spring tension in the diaphragm plunger head. In other words, in very cold temperatures, the extra tension created by the thermostatic coil will overcome the tension of the diaphragm plunger (bucking) spring to provide less choke valve opening with the results of slightly richer mixtures. In warmer temperatures, the thermostatic coil will have less tension and, consequently, will not press the spring as much thereby giving a greater choke valve opening for slightly leaner mixtures.

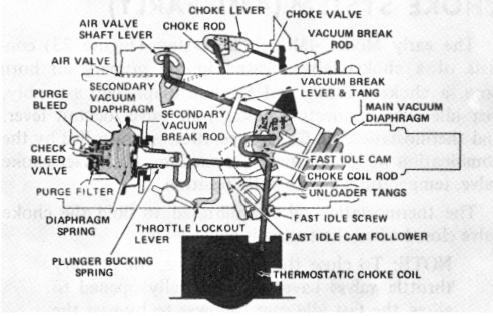

CHOKE SYSTEM (Fig. 22)

FIGURE 22