4. ACCELERATING PUMP SYSTEM

As the throttle opening is suddenly

increased

for acceleration, the air flow through

the carbu

retor responds almost immediately.

Since fuel,

however, is heavier than air, there

is a brief

interval before fuel flow responds

to the increase

in the throttle opening. During that

short period,

since the desired balance of fuel

and air cannot

be maintained by the other fuel metering

systems,

the accelerating pump becomes functional,

sup

plying fuel until the other metering

systems can

provide the proper mixture.

The accelerating pump, connected to

the

throttle lever by the pump link, is

actuated by

throttle movement. When the throttle

is moved

toward the closed position, the pump

piston is

raised by the linkage, charging the

accelerating

pump well with fuel. This upward movement

of

the piston draws fuel from the float

chamber

through the pump inlet and into the

pump well.

The pump inlet check valve opens to

permit fuel

to enter the pump well and closes

to prevent a

reverse flow of fuel when the pump

is in operation.

As the throttle is opened, the pump

rod is drawn

downward by the pump link. When the

pump rod

moves downward, the horizontal arm

in its upper

end slides down in the slot in the

piston stem,

compressing the pump spring.

This over-riding

feature of the pump discharge valve

provides a

ACCELERATING PUMP SYSTEM

prolonged, even discharge of fuel,

for smooth ac

celeration. The pressure of the compressed

spring moves the pump piston downward.

This

forces the fuel, in the bottom of

the pump well,

out through the pump discharge passage,

raising

the pump discharge needle valve. The

fuel flows

around the needle and is metered through

the

calibrated pump discharge nozzle into

the air

stream entering the venturi. The pump

discharge

valve prevents the syphoning of fuel

f rom the pump

well at high speeds, also prevents

air from enter

ing the pump chamber on the loading

stroke.

A larger or smaller accelerating pump

dis

charge, to compensate for climatic

conditions,

can be obtained by varying the position

of the pump

link pin in the holes provided in

the throttle lever.

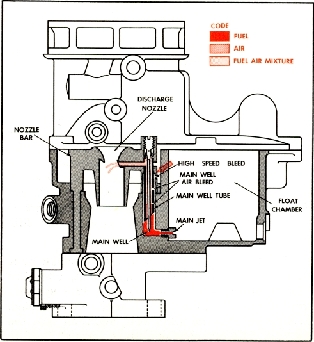

5. MAIN METERING SYSTEM

As the engine is running, the intake

stroke

of each piston draws the air through

the carbu

retor venturi and booster venturi.

The air, passing

through the reduced area of the venturi,

creates

a low pressure commonly called a

vacuum. The

strength of this low pressure is

determined pri

marily by the velocity of the air

flowing through

the venturi. This, in turn, is regulated

by the

speed and power output of the engine.

The dif

ference, between the pressure in

the venturi and

the normal air pressure in the float

chamber,

MAIN METERING SYSTEM