If the engine should

approach a stall at an

time during the warm-up period, manifold

vacuum

will become weak. The tension of the

thermosta

spring then overcomes the reduced force

actin

on the vacuum piston and the choke

plate will b

moved toward the closed position,

providing

richer mixture to allow the engine

to "catch" an

run smoothly again.

NOTE

Inasmuch as this dual carburetor has

two

identically functioning barrels, only

one side

will be considered in the following

explana

tions of the four basic fuel metering

systems.

AUTOMATIC CHOKE

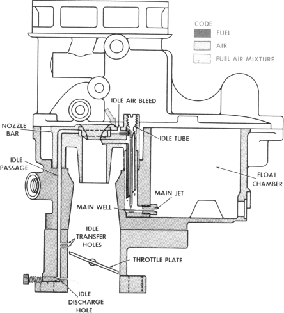

3. IDLE SYSTEM

At idle and low speeds, the engine

does not

draw sufficient air through the venturi

to create

a vacuum strong enough to operate

the main

metering system. Because of the almost

closed

throttle plates which greatly restrict

air flow into

the manifold at idle and low speeds,

manifold vacu

um is high. This high manifold vacuum

provides

a pressure differential which operates

the idle

system.

At idle, the greatly reduced pressure

area

below the throttle plates causes the

fuel to flow

from the float chamber through the

idle system.

From the float chamber, the fuel proceeds

through

the main jet into the main well, and

then into the

idle tube. The fuel moves upward through

the idle

tubes and flows through holes in the

side of the

head of the tube into the horizontal

channel of the

nozzle bar. The calibrated restriction,

in the

lower tip of the idle tube, meters

the flow of fuel

into the idle system. Air is added

to the raw fuel

by means of the idle air bleed in

the horizontal

channel. The booster venturi is circular

and the

fuel can flow through the channels

on either side.

After leaving the nozzle bar, the

fuel-air mixture

continues down the idle passage in

the throttle

body past the idle transfer holes

which act as ad

ditional air bleeds when the throttle

plate is in

the curb idle position. The fuel then

passes through

the idle discharge hole into the strong

manifold

vacuum below the throttle plates.

The idle dis

charge hole is equipped with an idle

adjusting

needle to control the mixture delivered

at idle.

During off idle operation, the throttle

plate

is moved slightly past the idle transfer

holes,

causing them to cease functioning

as air bleeds,

and begin to discharge fuel because

of being ex

posed to manifold vacuum. As the

throttle plate

is opened still wider and the engine

speed in

creases, the air flow through the

carburetor is

also increased. This creates a pressure

dif

ferential in the venturi strong enough

to bring

the main metering system into operation.

The

flow from the idle system tapers

off as the main

metering system begins discharging

fuel. The

two systems are engineered to provide

a smooth

even transition from idle to cruising

speeds.

IDLE SYSTEM