3. MAJOR SUBASSEMBLIES

Carburetor Model 2110 Series is composed

of three major subassemblies: the air

horn as

sembly, the main body assembly, and

the throttle

body assembly. The air horn contains

the choke

mechanism, the balance tube for venting

the float

chamber to the carburetor air inlet,

and the float

assembly which actuates the fuel inlet

valve. The

die cast main body contains the float

chamber, the

accelerating pump, the diaphragm type

power

valve, and the removable fuel metering

parts, such

as the main jets, idle tubes, and

booster venturi

nozzle bars. The cast iron throttle

body contains

the throttle plates and the idle speed

and mixture

adjusting screws. Carburetors used

with auto

matic transmission engines have a

bracket

fastened under the air horn screws

on which to

mount the dashpot assembly. Model

2110-EE and

2110-FF Carburetors have a choke bracket

or a

throttle control bracket. Carburetor

Model

2110-EEC has an automatic choke which

is an

integral part of the carburetor. Model

2110-G

has a built in Centri-Vac governor.

OPERATION

To meet the requirements of modern

auto

motive engines, the carburetor must

supply the

proper fuel-air mixture during all

phases of

operation. The Holley Carburetor Model

2110

Series, to provide the correct mixture,

is equipped

with four basic metering systems.

They are the

idle system, the accelerating pump

system, the

main metering system, and the power

enrichment

system. These four systems are individually

calibrated to deliver an economical

mixture for

normal cruising conditions; a richer

mixture when

high power output is desired, and

a still richer

mixture for smooth idle and low speed

perform

ance, also the accelerating pump provides

fuel

for instant acceleration.

In addition, there is a fuel inlet

system, which

provides the four basic metering systems

with a

constant supply of fuel, and also

a choke which

provides a means of temporarily enriching

the

mixture to aid in starting and running

a cold engine.

When the engine is running, differences

in air

pressure within the carburetor provide

the proper

discharge of fuel for the various

engine speed and

load conditions, as explained in

the following

paragraphs. In the explanation of

the basic fuel

metering systems, the air in the

carburetor float

chamber will be considered as being

at normal

atmospheric pressure. It may actually

be at a

pressure very slightly less than

atmospheric, due

to the restriction of the air flow

through the air

cleaner. However, to simplify the

explanation of

the function of the fuel metering

systems, this

factor will be disregarded and the

pressure will

be considered as being atmospheric.

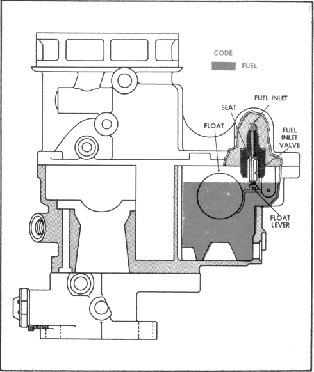

1.

FUEL INLET SYSTEM

All of the fuel, for the four basic

metering

systems, enters the carburetor through

the fuel

inlet valve. This valve is frequently

referred to

as the fuel inlet needle and seat

assembly. The

amount of fuel entering the carburetor

is deter

mined by the amount of space between

the tip of

the needle and its seat. Movement

of the needle

in relation to the seat is controlled

by the float

and lever assembly.

Movement of the float and

lever assembly is in turn regulated

by fluctuations

in the fuel level. Even a slight

drop in the fuel

level causes the lowering of the

float to open the

needle valve, allowing more fuel

to enter the float

chamber.

When the fuel in the float chamber

reaches a specified level, the needle

valve is

forced upward by action of the float

thus restricting

FUEL INLET SYSTEM