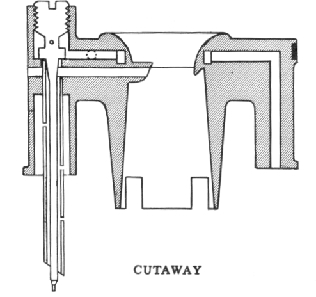

DESCRIPTION

1. DESIGN

Holley Carburetor Model 2110 Series

are all

dual downdraft carburetors. These dual

carbu

retors can be considered as two carburetors

built

side by side into one unit, but utilizing

the same

carburetor air inlet. Each side has

its own idle

system, main metering system, and

throttle plate.

All air bleeds and vents are supplied

with

filtered air from the air cleaner,

giving added

protection against the accumulation

of foreign

matter in the carburetor passages.

The main jets and idle tubes are individually

flow tested to insure precise calibration,

and meter

all fuel used during part throttle

conditions. The

accelerating pump system provides

the added fuel

for acceleration. An "override"

spring feature of

the accelerating pump, prolongs the

discharge of

fuel for smoother acceleration. The

added supply

of fuel necessary for high speed or

full power

operation is delivered by a fully

automatic power

enrichment system actuated by pressure

differ

ential acting across the economizer

diaphragm.

The booster venturi nozzle bars minimize

percolation effects by providing a

larger main

well with a long vertical rise. Percolation

occurs

on hot days after the engine has been

shut down.

The fuel in the bottom of the main

well is heated,

forming vapor bubbles which trap raw

fuel between

them as they rise. This action drains

the fuel

from the carburetor and deposits raw

fuel in the

intake manifold, making it difficult

to start the

engine. By incorporating larger main

wells and

longer passages, the bubbles break

as they rise.

No liquid fuel, therefore, is carried

into the hori

zontal passage leading to the main

discharge

nozzle.

2. APPLICATION

The application for these carburetors

are as

follows:

2110-EEC

Passenger Cars with

Automatic Choke

2110-EE Trucks

2110-FF Trucks

2110-G Trucks

NOTE

Carburetor part numbers and other

infor

mation applicable to specific vehicles

are

listed in the Holley Carburetor Parts

Catalog,

under the specific user.

BOOSTER VENTURI NOZZLE BAR