5.

First set one of the two idle adjusting

needles for the highest steady manifold

vacuum

reading. If a vacuum gage is not

available get the

smoothest running maximum idle speed

by turning

the idle adjusting needle in until

the rpm begins to

drop off, then backing the needle

off over the "high

spot" until the rpm again drops

off. Set the idle

adjusting needle halfway between

these two points

for a satisfactory idle mixture

setting. Then re

peat the procedure with the other

needle.

Final

fine adjustment may vary slightly

from this set

ting but should not exceed 1/2 turn

difference

between the screws. Should these

adjustments

show an increase in idle rpm, reset

the throttle

stop screw to obtain the specified

idle rpm and

adjust the idle adjusting needles

again.

B. ADJUSTING THE DASHPOT

The dashpot, on carburetors for

engines

equipped with automatic transmission,

is to be

adjusted after the idle speed and

mixture settings

have been completed. Close the throttle

lever

slowly to the idle position, with

the choke fully

open. Set the dashpot adjusting

screw to conform

to the clearance specified in the

Holley Carburetor

Company Parts Catalog.

C. ADJUSTING THE AUTOMATIC CHOKE

1. The automatic choke is accurately

set at the factory to give the best

possible all

weather operation. To return the

choke to the

original setting, line up the index

mark on the

rim of the thermostat cover with

the specified

indicator on the choke housing.

2.

If for some reason a richer or leaner

mixture during the warm-up period

is desired, it

can be obtained by rotating the

thermostat cover.

Never set the index mark on the

cover more than

two graduations off the large center

indicator on

the housing.

D. ADJUSTING THE GOVERNOR

1. Connect a tachometer to the engine.

Start the engine and allow it to

warm up thoroughly

Race the engine for a brief interval

at wide open

throttle and note the engine speed

registered by

the tachometer. If an adjustment

is required,

stop the engine and remove the

adjusting hole plug

from the governor valve housing.

With the ignition

switch off, crank the engine, either

by hand or

with the starter, until the governor

valve adjusting

screw at the end of the governor

valve body ap

pears at the opening. Insert a

screwdriver though

the hole and turn the adjusting

screw clockwise to

increase speed or counterclockwise

to decrease

speed. One full turn of the adjusting

screw will

result in a change in top speed

of about 150 rpm.

Repeat the adjustment procedure

until the speed

is set to specifications. Install

the adjusting hole

plug and tighten securely. Attach

new locking

wire and seal to the adjusting

hole plug and the

adjacent fin.

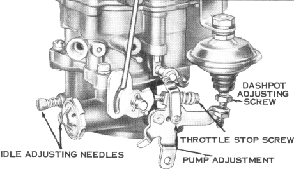

Figure 40. Carburetor Adjustments

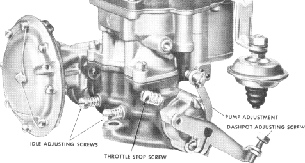

Figure 41 . Carburetor Adjustments

SERVICE HINTS

Carburetor service should be performed

only

with the use of proper equipment.

Approved equip

ment includes float setting gages,

together with

other special carburetor tools.

In addition, ap

proved specification sheets must

be utilized. Refer

to the Holley Carburetor Catalog

sheet for the

carburetor being overhauled to

find the proper

engine and carburetor specifications.

1. INSPECTING THE VEHICLE