3. Install the dashpot adjusting

screw

and nut (If included).

4. Install the throttle stop screw

and

spring.

5. Install the throttle stop screw

and

spring. While holding the throttle

plates almost

closed, turn the screw in until

its tip contacts the

tab at the end of throttle operating

shaft lever.

5. Slide the fast idle cam on the

stud

and install the fast idle cam retainer.

- Model

2110-EEC.

6. Slide the throttle lever assembly

in

place and insert throttle lever

clamp screw and

nut.

6. Install the spark valve assembly

with a new gasket. (If included).

7.

Install the two idle adjusting springs

and needles.

B.

REASSEMBLY - THROTTLE BODY

ASSEMBLY MODEL 2110-G

1. Install bearing on governor side

of

the throttle body. Slide the throttle

shaft and bear

ing assembly into the throttle body,

and install

bearing retainer. (Correct position

of shaft noted

during disassembly.)

2. Referring to lines and figures

scribed

on the throttle plates during disassembly,

install

the throttle plates. Insert the

four throttle plate

screws snugly, but do not tighten.

Close the throt

tle plates and hold the throttle

body up to the light.

Little or no light should show between

throttle

plates and the walls of the throttle

bores. If the

throttle plates are properly aligned,

there will be

no binding when throttle lever is

operated. Using

an approved staking tool, tighten

the throttle plate

screws. If it is necessary to use

an impact type

of staking tool, be sure to back

up the heads of the

throttle plate screws to prevent

bending the throttle

shaft when staking.

3. Install the throttle operating

shaft

assembly in throttle operating housing.

Position

the two screws and lockwashers in

the housing.

Place the new gasket over the ends

of the screws

and with the throttle plates held

in the closed

position, set the assembly in place

on throttle

body, making sure the throttle

operating shaft

lever assembly is in the open position.

If the as

sembly is properly installed, the

throttle plates

will be closed when the throttle

operating lever

is up.

4. Install the dashpot adjusting

screw

and nut in the throttle lever clamp.

(If included).

7.

Install the two idle adjusting

needles,

with the original springs. Turn

the needles by

hand until they seat in the idle

discharge holes.

Then back them off one complete

turn. Do not

force the needle against its seat,

as this will groove

the tip of the needle, make it

impossible to correctly

adjust the idle mixture.

8. Place the diaphragm and rod

as

sembly in the governor housing.

Take care that

all the holes in the diaphragm

are aligned with

the threaded holes in the rim of

the governor

housing. The bent end of the rod

should point out.

Place the diaphragm cover in position,

making

sure the vacuum passage holes in

the governor

housing, diaphragm and diaphragm

cover are all

correctly aligned. Insert the diaphragm

cover

screws and lockwashers, spacing

evenly the three

screws drilled for the safety wire.

Turnthescrews

in until the flanges almost meet

but do not tighten.

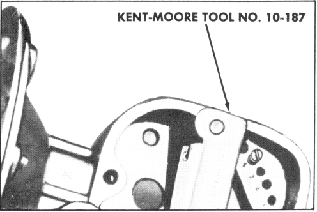

Place the governor diaphragm gage

(Kent-Moore

Tool No. 10-187) on the governor

housing as shown

in the illustration. Hook the end

of the diaphragm

rod into the slot provided in the

gage, and then

tighten the eight diaphragm cover

screws securely

before removing the gage. This

procedure will

stretch the diaphragm sufficiently

to insure full

travel of the diaphragm for proper

governor oper

ation. Install a new safety wire

and seal.

Figure 35. Installing Governor

Diaphragm Cover