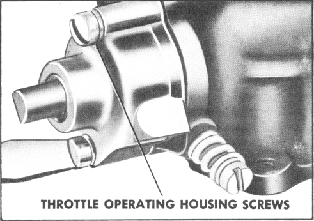

Figure 32. Removing Throttle Operating

Housing Screws

12.

Slide the throttle operating shaft

out

of the housing.

Remove the throttle stop screw

and spring.

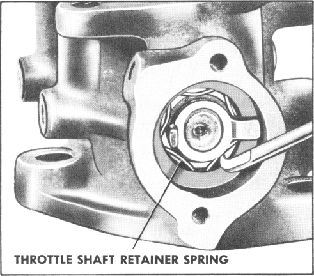

13. Using Kent-Moore Tool No. 10-188,

lift the wire throttle shaft retainer

spring out of

the slot in the throttle body.

Figure 33. Removing Throttle Shaft

Retainer

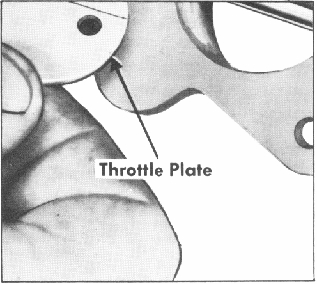

14. Lightly scribe both throttle

plates

along the throttle shaft and mark

each throttle

plate and its corresponding bore

with a number

or letter to insure proper replacement.

15. Remove the four throttle plate

screws, and slide the throttle plates

out of the

throttle shaft. Remove the throttle

shaft and

bearing assembly from the throttle

body. (Note

position of shaft for correct reassembly.)

Re

move the remaining bearing from

governor side

of the throttle body.

Figure 34. Removing Throttle Plates

5. CLEANING AND INSPECTION

A. CLEANING

1. Soak all castings and metal parts,

except the dashpot assembly and

nozzle bars, in

a cleaning solution until all foreign

deposits are

loosened. If a commercial cleaning

solvent is not

available, lacquer thinner or denatured

alcohol

may be used. Place the parts to

be cleaned in a

metal basket suspended in the solution

and agitate.

Avoid lowering the basket into the

sediment which

collects in the bottom of the container.

After the

parts have soaked sufficiently,

they are to be

rinsed in hot water to remove all

traces of the

cleaning solution. Scrub away all

remaining for

eign matter with a stiff bristle

brush while rinsing

the parts and castings. Only inlet

end of the noz

zle bars should be immersed in the

cleaning

solvent. DO NOT place the circular

booster

venturi in the solution.

2. Parts and castings should be

thor

oughly dried with compressed air.

Compressed

air should also be directed through

all passages

in the castings and through the

jets and nozzle

bars.

CAUTION

Carburetor jets and passages should

never

be cleaned with a wire, a drill,

or similar

abrasive objects. This method of

cleaning

may distort the jets and passages

and greatly