plates are properly installed, tighten

the throttle

plate screws and stake them.

be installed before installing the

choke shaft. See

step 12 following.

3. Replace the idle speed screw and

spring.

Turn the idle speed screw in approximately

14

complete turns.

4. Install a new throttle operating

shaft gasket

and, with the throttle plates held

in the closed

position, place the throttle operating

shaft into

place in the throttle body. The

accelerating pump

lever of the throttle operating

shaft should extend

toward the fuel inlet side of the

throttle body and

should be held down in the wide-open

throttle po

sition. When this assembly is properly

installed,

it should hold the throttle plates

closed when the

accelerating pump lever is up, but

should permit

the plates to move freely when the

lever is down.

11. Referring to the numbers and

lines scribed

on the choke plates during disassembly,

install the

choke plates, choke plate screws,

and lockwashers.

Carefully check to make sure the

choke plates work

freely and do not rub on the nozzle

tube extensions.

12. On carburetors having the choke

lever

separate from the choke shaft, install

the choke

bracket and choke lever and tighten

the choke

lever clamp screw.

5. Place the throttle operating

shaft housing

and hand throttle bracket in position

and install

the two throttle operating shaft

housing screws and

lockwashers.

6. Install the throttle lever. Carefully

line

up the hole in the throttle lever

with the hole in the

throttle operating shaft and drive

the throttle lever

pin in place. Tighten the throttle

lever clamp

screw.

7. Press the throttle shaft bearing

on the

governor side of the carburetor

into position.

8. Install the new idle adjusting

needles with

the original springs. With the fingers,

turn the

idle adjusting needles in until

they seat in the idle

discharge hole, then back them out

one full turn.

Be careful not to force either needle

against its

seat, as this will groove the tip

of the needle,

making it impossible to correctly

adjust the idle

mixture.

9. Place the new distributor check

valve ball

in its passage and install the

check valve retainer.

On the carburetors which also require

a check

valve spring, install the ball,

spring, and retainer,

in that order.

10. Install the choke shaft and

drum-like

nozzle tube extensions. Be sure

the narrow end

of the egg-shaped hole in each

nozzle tube extension

faces toward the idle adjusting

needle side of the

throttle body. On carburetors which

have the choke

lever riveted to the shaft, the

choke bracket must

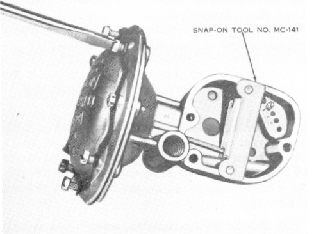

FIGURE 53. PROPER DIAPHRAGM STRETCHING

PROCEDURE

13. Place the new diaphragm and

rod as

sembly in the governor housing,

being sure that

all holes in the diaphragm are

aligned with the

threaded holes in the rim of the

governor housing.

The bent end of the rod should

point out. Place

the diaphragm cover in position,

being sure the

vacuum passage holes in the governor

housing,

diaphragm, and diaphragm cover

are all correctly

aligned. Insert the eight diaphragm

cover screws

and lockwashers, spacing evenly

the three screws

drilled for lock wiring. Turn the

screws in until

the flanges nearly meet but do

not tighten the

screws. Pull the end of the diaphragm

rod back

firmly to a point directly above

the threaded hole

for the governor cover screw at

the bottom of the