21. Remove the idle speed adjusting

screw

and spring from the throttle body.

S. CLEANING AND INSPECTION

A. Cleaning

22. Lightly tap the throttle body

with a fiber

mallet to loosen and remove the

throttle shaft

bearing at the governor end of the

throttle shaft.

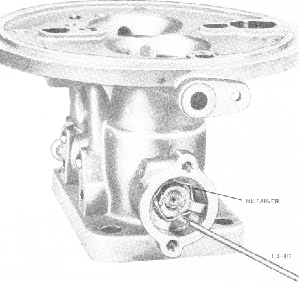

FIGURE 50. REMOVING THROTTLE SHAFT

RETAINER

23. With Snap-On Tool No. MC-95,

lift the

wire throttle shaft retainer out

of the slot in the

throttle body and slide the throttle

shaft with

attached bearing out of the throttle

body.

1. Soak all castings and metal parts,

except

the dashpot and spark valve body,

in a cleaning

solution long enough to loosen all

foreign deposits.

If a commercial cleaning solvent

is not available,

lacquer thinner or denatured alcohol

may be used.

Place the parts and castings to

be cleaned in a

metal basket suspended in the solution

to keep

them out of the sediment which collects

in the

bottom of the container. Agitating

the parts in

the solution usually promotes a

more thorough

cleaning. After the parts have soaked

sufficiently,

rinse them in hot water to remove

all traces of

the cleaning solution. While rinsing

the parts and

castings, scrub away all remaining

foreign matter

with a stiff bristle brush.

2. Soak each part and casting in

clean gasoline

for a few seconds and dry them with

compressed

air. Compressed air should also

be directed

through all passages in the castings

and through

all jets and tubes.

3. The dashpot and spark valve body

should

not be exposed to the solvent, as

most commercial

solvents will deteriorate the neoprene

diaphragms

in these units. Their exteriors

may be cleaned

with a rag dipped in gasoline and

wrung almost

dry. They should not be dried with

compressed

air as the compressed air may rupture

the dia

phragms.

CAUTION

Carburetor jets and passages should

never

be cleaned with a drill, wire or

similar

object. This method of cleaning

may dis

tort jets and passages, and affect

carbu

tor performance. A buffing wheel,

wire

brush, file, or other sharp instrument

should not be used to remove carbon

de

posits, as the protective plating

on the part

might be removed by scratching

or filing.

NOTE

Parts such as the accelerating

pump pis

ton, gaskets, diaphragms and felt

seals,

should never be exposed to the

cleaning

solvent. Most commercial solvents

will

deteriorate these parts.

FIGURE 51. REMOVING THROTTLE SHAFT,

BEARING, AND THROTTLE PLATES

4. The air cleaner should be cleaned

at this

time to insure proper carburetor

performance.

"'BOTTLE RLA

THROTTLE SHAFT GEARING

'' >OVF