upshifted to high range, a forced downshift can be made by

moving the manual linkage into low range.

CAUTION: Do not force a downshift at speeds above

normal "through detent upshifts" speed. See the Power

glide shift point chart in the appropriate Chassis Service

Manual for specific vehicle speeds.

Since the transmission has already upshifted to high range,

governor pressure holds the low-drive shift valve in the full

right position, the high clutch circuit exhaust port is blocked.

Thus, to shift the transmission to manual low, the normal low

range circuits are charged and the high clutch oil exhausts at

the manual valve (fig. 25PG). As this pressure exhausts, the

transmission downshifts to low range.

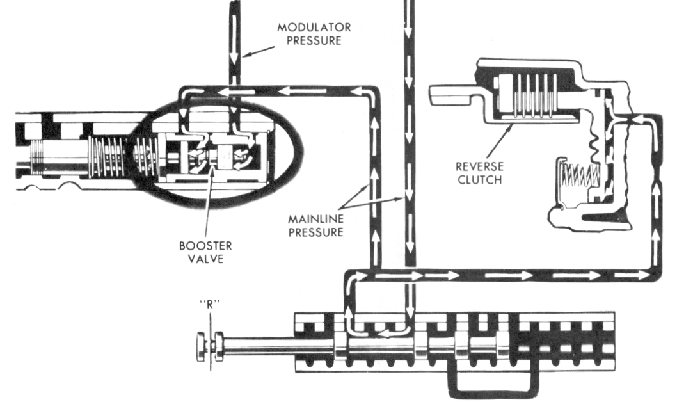

Fig. 25PG-Downshift to Manual Low

The vacuum modulator valve receives mainline pressure

through the normal passage and through the exhaust passage.

This prevents the modulator valve from regulating and applies

full mainline pressure to the booster valve. This action causes

mainline pressure to be regulated at a higher value. The in

creased mainline pressure offsets the higher torque reactions

associated with manual low range.

"D" To Manual Low Downshift

Reverse Circuit

With selector lever in the reverse or "R" position, the

manual valve directs mainline pressure only to the reverse cir

cuit. The high clutch and low servo circuits are all open to

exhaust at the manual valve. Pressure leaving the manual valve

and entering the reverse circuits is fed to the reverse clutch and

to the booster valve (fig. 26PG). The combined pressure of

modulator pressure on one spool, and mainline between the

spools causes the pressure regulator to increase mainline

operating pressure to its maximum.

Fig. 26PG-Reverse Circuits