transfer holes which act as additional

air bleeds.

(There is only one idle transfer hole

on truck car

buretors.) The fuel is discharged from

the idle

discharge hole into the strong manifold

vacuum

below the throttle plates. The idle

discharge hole

in both throttle bores is equipped

with an idle ad

justing needle which is used to control

the mixture

delivered at idle only. Turning the

needle in toward

its seat restricts the flow of fuel,

thus providing a

leaner idle mixture. Turning the needle

out en

riches the mixture by allowing a greater

flow of

fuel. Directly under the idle needles

is a groove

in the manifold mating surface of

the throttle body.

This groove allows manifold heat to

warm the area

around the idle discharge holes and

eliminates

the possibility of icing.

During off-idle operation when the

throttle

plate is moved slightly past the idle

transfer holes,

the idle transfer holes begin discharging

fuel as

they are exposed to manifold vacuum.

As the throt

tle plate is opened still wider and

engine speed

increases, the air flow through the

carburetor is

also increased. This creates a vacuum

in the

venturi strong enough to bring the

main metering

system into operation. The flow from

the idle

system tapers off as the main metering

system

begins discharging fuel. The two systems

are

engineered to provide a smooth gradual

transition

from idle to cruising speeds.

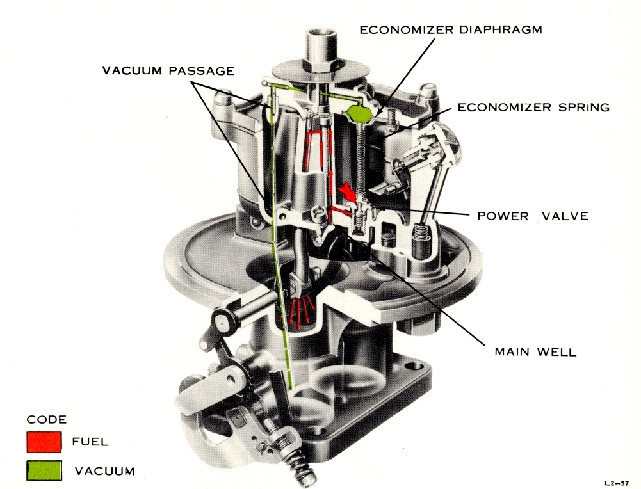

POWER ENRICHMENT SYSTEM

4. POWER ENRICHMENT SYSTEM

During high power operation, the carburetor

must deliver a richer mixture than

is needed when

the engine is running at cruising

speed with no

great power output required. The added

fuel for

efficient operation is supplied by

the power en

richment system, sometimes referred

to as the

economizer system.

The power enrichment system is controlled

by manifold vacuum, which gives an

accurate

7-