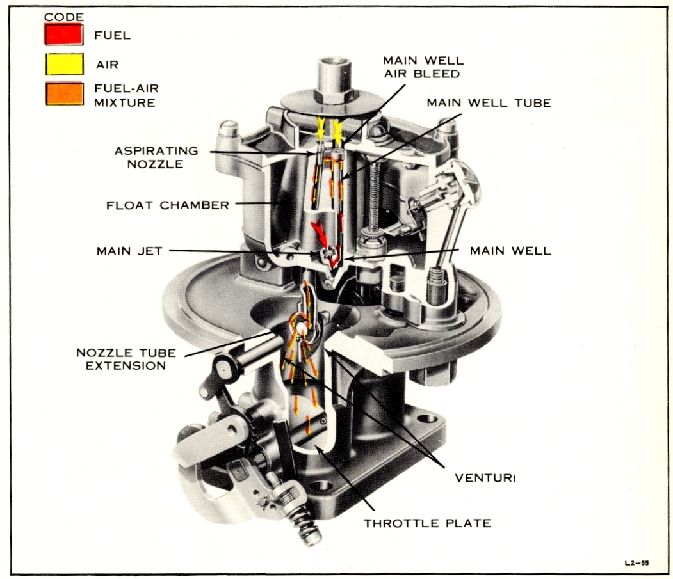

MAIN METERING SYSTEM

turn, is regulated by the speed and

power output

of the engine. The difference between

the reduced

pressure, or vacuum, in the venturi

and the normal

air pressure in the float chamber causes

fuel to

flow through the main metering system.

At cruising speed, the fuel flows

from the

float chamber through the main jet,

which meas

ures or meters the fuel, into the

bottom of the

main well. The fuel moves up the main

well and

past the narrow air bleed holes in

the side of the

main well tube. Air, which enters

the main well

tube from the main well air bleed,

is added to the

fuel by these air bleed holes. This

mixture of fuel

and air, being lighter than raw fuel,

responds faster

to any change in venturi vacuum, and

vaporizes

more readily than raw fuel when discharged

into

the air stream in the venturi. Additional

air from,

the aspirating nozzle enters the fuel

as it passes

from the top of the main well to the

vertical pas

sage leading to the nozzle tube extension.

This

mixture of fuel and air is then discharged

into the

air stream in the venturi through

the drum-like

nozzle tube extension which aids fuel

distribution.

The throttle plate controls the amount

of the fuel

air mixture admitted to the intake

manifold, regu

lating the speed and power output

of the engine in

accordance with accelerator pedal

movement.

There are identical main metering

system pas

sages for both barrels of this dual

carburetor

and they function simultaneously as

described

above.