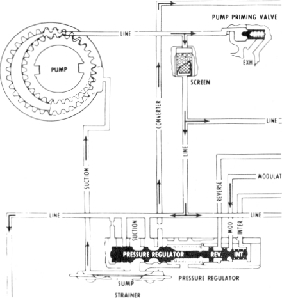

Fig. 27M-Pump Pressure

reverse to get the maximum apply load. Reverse oil is directed

to the pressure regulator valve (fig. 26M) to increase the main

line pressure. Reverse oil is applied directly to the large areas

of these two clutches and to the small areas via the shift valves.

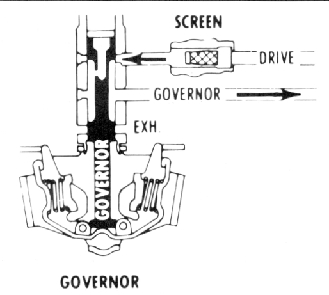

Fig. 28M-Governor

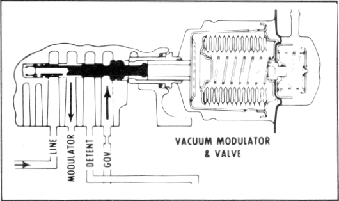

Fig. 29M-Vacuum Modulator

Oil Pump Pressure Regulation

Pump Oil Pressure is obtained when the Engine and Con

verter drive the Pump Gears, which compress oil sucked

through the oil strainer. Air in the circuit is expelled at the

Priming Valve until oil pressure reaches 5 P.S.I.

The Oil Pressure is regulated by the Pressure Regulator

Valve and Spring (fig. 27M). The Boost valves aid the spring

to increase the pressure when Modulator, Reverse, and/or

Intermediate oil is fed to the Reverse and Intermediate Boost

Valve lands. High boost results in High Line Pressure.

Oil from the Pressure Regulator Valve feeds the Converter.

This oil is also directed to the Modulator, 1-2 Accumulator,

Detent Regulator, and Manual Valve. Manual valve position

directs oil to the Governor, Shift Valves, 2-3 Accumulator, and

Intermediate Servo, to apply the Clutches and Band.

Governor Regulation of Pressure (Fig. 28M)

The Car Speed signal to the transmission is governor

pressure (regulated from drive oil pressure) which moves the

shift valves to obtain the 1-2 and 2-3 shifts.

High Car Speed results in high governor pressure.

Vacuum Modulator Regulation of Pressure (Fig. 39)

Engine vacuum indicates carburetor (throttle) opening and

engine torque required. This signal (vacuum) moves the

vacuum modulator diaphragm assembly which actuates the

modulator valve to regulate lin pressure into modulator

pressure (fig. 29M). High vacuum (Low torque signal) results

in low modulator pressure; low vacuum (high torque signal)

results in high modulator pressure.