9D-3

|

|

|

|

|

|

|

|

|

|

|

|

MODELS 2G-2GC-2GV PAGE 16

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

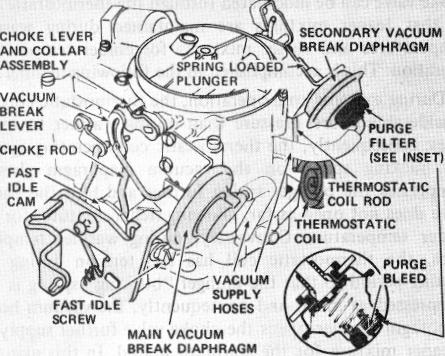

When the engine starts and the choke vacuum break diaphragm seats, the closing spring hits a stop on the plunger stem and no longer exerts pressure on the vacuum break rod.

|

|

As the engine continues to warm up, the choke coil continues to relax its tension until the choke valve is fully opened and the engine can now run at normal fuel mixtures.

|

DUAL VACUUM BREAK SYSTEM (2GV)

|

|

|

|

A clean air purge feature is added to the choke auxiliary vacuum break unit on some 2GV models. The purpose of the clean air purge is to bleed air into the auxiliary vacuum break circuit and purge the system of any fuel vapors or dirt contamination which might be pulled into the bleed check valve located inside the diaphragm unit. The purge system consists of a small bleed hole located in the vacuum break diaphragm tube just beneath a filter element covered by a rubber boot. During engine operation, vacuum acting upon the diaphragm unit pulls a small amount of filtered air through this bleed hole to purge the system.

|

(Fig. 25)

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

|

|

|

| |

|

|

A slight change in secondary vacuum break adjustment procedure is necessary for those units using the clean air purge feature. (See Adjustment Procedure Bulletin in the 9D-3 Section of the Delco Carburetor 9X Parts and Service Manual.)

|

| |

|

|

|

|

|

| |

|

|

MODEL 2G TRUCK

|

|

| |

|

|

VACUUM CONTROLLED GOVERNOR (See Fig

|

| |

|

|

|

|

|

|

|

|

|

ure 26)

|

|

|

| |

|

|

|

FIGURE 25

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

The purpose of the Model 2G governor carburetor is to prevent excessive engine speed under light loads by partially closing the throttle valves, but yet allow the throttle valves to be wide open when full power is required. The governor gives full advantage of engine horsepower without danger of excessive engine wear due to overspeeding.

|

| |

|

|

|

|

|

|

|

|

|

Other Rochester 2GV carburetors use a dual vacuum break system consisting of a main vacuum break unit, and a second or auxiliary vacuum break unit for improved operation during cold start and drive-away.

|

|

The two vacuum break units are used for refined fuel mixture blending during the initial cold start and cold running periods. The main vacuum break diaphragm opens the choke valve to a point where the engine will run without loading or stalling. As the engine manifold is wetted and friction in the engine decreases, the second auxiliary vacuum unit which has a delayed action, gradually opens the choke valve a little further to prevent loading.

|

|

The governor operates in connection with a spinner unit in the distributor. However, the carburetor systems are the same as those we have just discussed.

|

| |

The throttle shaft is unusual in that it is equipped with ball bearings to reduce friction for proper governor operation.

|

| |

The governor is a mechanically driven vacuum actuated mechanism set to govern engine speed at 3700-4000 RPM maximum under full load conditions. The RPM limits established an excellent pattern for shift control for automatic type transmissions.

|

The main vacuum break unit located on the throttle lever side operates the same as on previous units. The auxiliary vacuum break unit located at the opposite end of the choke shaft has a delayed action created by an internal check valve which has a very small bleed orifice. This delays the movement of the vacuum diaphragm a few seconds until the engine will run at slightly leaner mixtures.

|

|

| |

The governor is comprised of two basic units; the centrifugal control valve housed in the distributor, and a carburetor actuator which is mounted on the carburetor throttle body. These two components are inter-connected by tubing.

|

Included in the secondary vacuum break unit is a spring-loaded plunger. The purpose of the spring-loaded plunger is to offset choke thermostatic coil tension and balance greater opening of the choke valve, with tension of the choke coil. This enables further refinement of the fuel mixtures during the warm-up period because the choke coil, which senses engine temperature, will allow the choke valve to open gradually against the spring tension in the diaphragm plunger head.

|

|

| |

The vacuum diaphragm mounted in a housing on the carburetor throttle body closes the throttle valves through connecting linkage. The governor spring located in the governor housing opens the throttle valves and works against the vacuum diaphragm.

|

| |

The throttle lever on the opposite end of the throttle shaft is not connected directly to the throttle shaft. When

|