9D-3

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MODELS 2G-2GC-2GV PAGE 4

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

mixtures are regulated by a drop in engine manifold vacuum, or carburetor venturi vacuum (Vega), regardless of the degree of throttle opening. Additional fuel is supplied for power mixtures according to engine demands.

|

|

The pump system uses a vented type pump plunger. On early models, this is accomplished by means of a vapor vent ball in the pump plunger head; on later models, venting is accomplished by means of the "floating" pump cup. In this way, any fuel vapors that form in the pump well are vented to the float bowl during hot engine operation. Venting of the pump plunger assures the pump well and passages will be primed with solid fuel at all times for adequate accelerator pump action.

|

|

The main metering jets are a fixed orifice type so that wearing parts can be kept to a minimum. Metering calibration is accomplished through a system of calibrated orifices and air bleeds which supply the correct air/fuel mixtures to the engine throughout all operational ranges. The carburetor float bowl is located so that each system will give instantaneous response for maximum efficiency and performance.

|

|

| |

|

|

|

|

|

|

| |

|

|

|

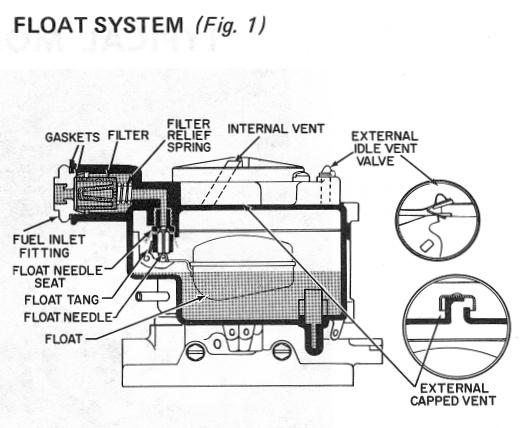

FIGURE I

|

|

|

SERVICE FEATURES

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

discharge nozzles on turns, and engine loading can result. If the fuel level is lower than the specified setting it can cause lean mixtures, hesitation on acceleration, engine surge, plus engine cut-out during heavy fuel demands.

|

The Model 2G, 2GC, 2GV Rochester Carburetor has been kept basically simple for ease of service.

|

|

|

The power enrichment valve on the Chevrolet Vega 2GV model is serviced as a complete assembly.

|

|

|

| |

|

|

The float system operates as follows:

|

|

Power restrictions, where used, are pressed into the float bowl and have no wearing parts, thereby making replacement unnecessary.

|

|

|

|

|

| |

|

Fuel from the engine fuel pump is forced through the fuel inlet screen or filter, and on through the float needle seat, past the float needle, into the float bowl. Fuel flow continues until the fuel raises the float pontoon to a position where it forces the float needle against the float needle seat and shuts off fuel flow. As fuel is used from the carburetor bowl during engine operation, the float again drops downward, moving the float needle off its seat, allowing more fuel to flow into the float bowl, thereby keeping the fuel level constant.

|

All field adjustments have been made as simple as possible. There are no adjustments required for the part throttle or power system.

|

|

|

For ease in servicing, special tools, gauges, and field adjustments have been kept to a minimum.

|

|

|

OPERATING SYSTEMS

|

|

|

|

|

|

There are six basic systems used in the Rochester Model "G" 2-bore carburetor. They are float, idle, main metering, power, accelerator pump and choke systems. The following text will describe the operation of these systems for ease in trouble-shooting. The recommended disassembly, cleaning, inspection and assembly procedures are also given.

|

|

|

The float drop tang located at the rear of the float arm prevents the float from moving too far downward. The maximum float drop must be maintained so that the float assembly will drop sufficiently to allow maximum fuel flow under heavy engine fuel demands. Some models use a float needle pull clip which is attached to the float arm and connected to the float needle valve. The purpose of the pull clip is to pull the float needle off its seat, should it stick closed due to dirt or gum formations.

|

For specific adjustment procedures and specifications for each particular carburetor, refer to the "D" Section of the 9X Parts and Service Manual.

|

|

|

|

|

|

|

|

|

|

|

|

|

The shapes of the floats vary somewhat, and along with them the method of checking the float level.

|

FLOAT SYSTEM (Figure 1)

|

|

|

|

|

The carburetor float system controls the fuel level in the carburetor bowl. Fuel level is very important because it must be maintained to give proper carburetor metering throughout all ranges of engine operation. If the fuel level is too high in the float bowl, problems such as rich mixtures affecting mileage and emissions, fuel spillage from the main

|

|

|

Some 2G carburetors use a spring-loaded float needle. Under erratic fuel level conditions due to rough roads, vibration, etc., this spring keeps the fuel level from creeping up and causing flooding of the engine.

|

| |

|

Some units are equipped with an integral fuel inlet filter located behind the fuel inlet fitting. The filter assembly

|